5 Warehouse Layout Mistakes to Avoid for Maximum Efficiency

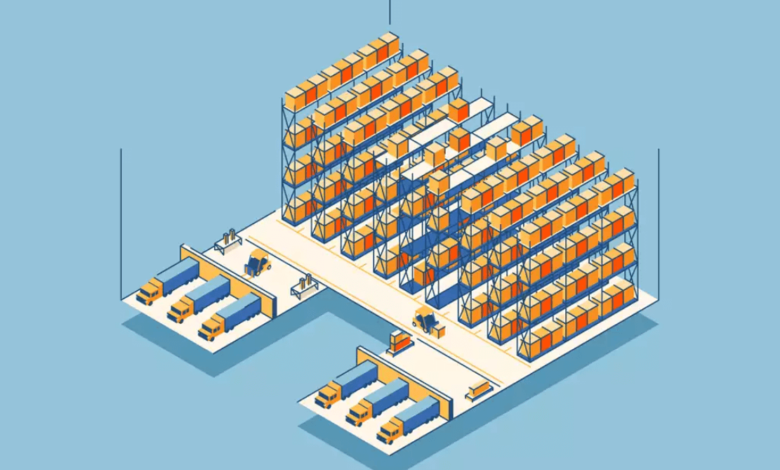

Efficient warehousing is critical for supply chain efficiency. It’s mandatory for managing and fulfilling orders timely and accurately. A well-organized warehouse will maintain inventory levels and reduce operational costs. Warehousing inefficiencies can result in delayed shipments, excess inventory, and unsatisfied customers.

Therefore, you should invest in a robust warehouse management system to streamline warehousing operations. However, it may not help if your warehouse layout is poorly designed. Layout mistakes can lead to operational bottlenecks that even robust software may not overcome.

5 Common Warehouse Layout Mistakes to Avoid

1. Not Considering Workflow

One of the most common mistakes is ignoring workflow in the design process. For instance, if workers have to move back and forth to access frequently used items, it wastes a lot of time. The layout should be designed to reduce unnecessary movement by placing in-demand products near packing and shipping areas.

When designing the layout, analyze your current workflows and aim for travel time for picking products. Try to group items based on their demand and strategically place them for easy access.

2. Underutilization of Vertical Space

Warehouses often have vast vertical spaces that are often ignored by business owners. It’s a major layout mistake that leads to a shortage of space during peak seasons. Not utilizing vertical space leads to overcrowded floor areas, making it harder for employees to navigate. It also makes it hard for them to use equipment to lift heavy items. All these complexities decrease their productivity.

You can avoid this by investing in appropriate shelving. It will allow you to store products without consuming floor space. Apart from that, you can also opt for mezzanine systems to make full use of vertical space. The key thing you need to focus on is to invest in appropriate machinery that helps your team access higher levels safely and efficiently.

3. Inadequate Dock Design

The loading dock is one of the busiest areas in a warehouse. An inefficient dock layout can lead to congestion. It will slow down both the receiving and shipping processes. If it isn’t designed for the smooth flow of goods, delays and errors in shipments will occur.

You can avoid this mistake by placing docks in locations that allow for easy access to storage areas. It will save a lot of time as workers don’t have to cross the warehouse unnecessarily. You should design dock areas with separate zones for receiving and shipping to avoid cross-traffic. It ensures that enough space is allocated for staging areas.

4. Lack of Flexibility

As a business owner, you always want to grow your business. When it grows, your warehousing requirements change. To meet these requirements, you need to change the layout of your warehouse. It means a rigid layout that cannot adapt to changes can quickly become inefficient. As a result, you will fail to manage seasonal demand shifts or product line expansions.

When you plan layout, keep your focus on flexible designs. You should opt for modular shelving and mobile storage units as they can be easily adjusted to accommodate changing requirements. Above all, you should regularly review your layout to ensure it supports current and future operations.

5. Inefficient Use of Technology

Technology has evolved a lot over the past few decades. In this technologically advanced era, cannot rely on outdated manual processes to manage warehouse operations. Doing so will result in errors while consuming a lot of time in managing different tasks. Without automation human error and inefficiencies are inevitable. You also need advanced technology to track inventory, schedule tasks, or optimize the layout.

You should invest in advanced warehouse management software for efficient inventory management. It will help you track stock levels, manage workflows, and ensure that the warehouse layout is functioning optimally. Moreover, real-time data from a WMS can provide insights into inefficiencies. It allows you to continuously improve your layout and warehouse processes. You should always opt for a flexible and scalable software system that can accommodate the changing warehouse requirements.

Read also: Generative AI Use Cases and Applications

Bottom Line

Managing warehouse operations is no longer a challenge for you. All you need to do is to avoid the aforementioned layout mistakes. Apart from that, you should invest in a WMS as well. It will not only help in optimizing layout but streamline various operations as well.