How Acetylene Gas Revolutionises the Production of Advanced Medical Equipment

Have you ever wondered what makes advanced medical apparatus so precise and effective? One such game-changer is acetylene gas. This gas is transforming various industries, including healthcare. But what exactly makes acetylene so unique for producing medical tools?

In the quest to create state-of-the-art medical equipment, manufacturers continuously seek methods that ensure precision and reliability. It plays a crucial role in this process, offering numerous advantages that traditional methods lack. This article explores its benefits and applications in crafting advanced medical instruments.

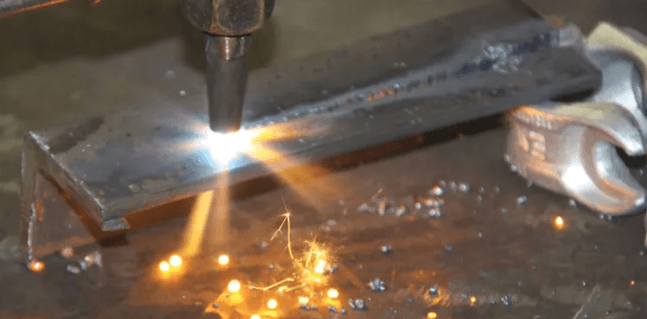

Precision in Welding and Cutting

Welding and cutting are integral processes in the production of surgical devices. It enables precise and controlled operations, essential for creating complex and delicate components. For example, surgical instruments and diagnostic tools require meticulous assembly, ensuring each part is flawlessly joined and formed.

Acetylene welding provides unmatched accuracy. It allows manufacturers to produce tools with minimal imperfections, enhancing their reliability and performance. This level of precision is fundamental in the medical field, where the efficacy and safety of equipment are paramount.

Enhanced Material Properties

Using it in manufacturing improves precision and enhances the materials’ properties. The gas facilitates the creation of more robust and durable components. This durability is essential for devices that must withstand rigorous sterilisation and repeated use without degrading quality.

For instance, the production of surgical instruments benefits significantly from acetylene’s ability to produce hard-wearing materials. These instruments must remain sharp and reliable over time, and it ensures they meet these stringent requirements.

Innovations in Manufacturing Techniques

Acetylene gas has also led to significant innovations in manufacturing techniques. Its high-temperature capabilities enable advanced methods like flame spraying, where materials are applied to surfaces to create protective coatings. This technique enhances the longevity and performance of medical devices, ensuring they remain effective under various conditions.

Additionally, acetylene’s versatility allows for the developing of new manufacturing processes tailored to specific medical applications. This adaptability ensures that as technology evolves, production methods can keep pace, continually improving the quality and functionality of medical tools.

Environmental and Economic Benefits

Beyond its technical advantages, acetylene gas offers environmental and economic benefits. Its efficiency means less energy consumption, reducing the carbon footprint of manufacturing operations. This is a significant benefit for companies focused on sustainability, aligning with global efforts to minimise environmental impact.

Economically, acetylene’s cost-effectiveness allows manufacturers to allocate resources more effectively. Savings from reduced energy use and increased production efficiency can be redirected towards innovation and improving existing products, driving further advancements in medical technology.

Safety in Production

Safety is critical in any manufacturing process, mainly when producing medical devices. When handled correctly, it provides a safe and reliable option for manufacturers. Modern safety protocols and equipment ensure that the use of acetylene is controlled and secure, minimising risks to workers and facilities.

These safety measures are essential for maintaining consistent production quality and protecting the workforce. By adhering to stringent safety standards, manufacturers can continue leveraging the benefits without compromising safety.

Global Impact and Future Potential

Its impact on medical device production is felt worldwide. Its use has led to the developing of advanced equipment that improves healthcare outcomes globally. As technology progresses, the potential for further innovations in manufacturing using acetylene is vast.

Future research and development in this area promise to unlock even more applications for acetylene gas, ensuring that the production of medical tools continues to evolve. This progress will lead to better healthcare solutions, enhancing the trait of life for countless individuals.

Acetylene gas revolutionises the production of advanced medical equipment by offering precision and innovation. Its unique properties enable the creation of high-quality devices essential for modern healthcare. Manufacturers can produce reliable and durable medical tools by leveraging acetylene gas, ensuring that healthcare providers have the best equipment.